| 材质 | PPS |

|---|---|

| 适用范围 | 风机,水族类,油箱,咖啡机,过滤壶,医用,空气净化器,挖掘机,过滤器,汽车发动系统,净水器,水泵,离心机,水槽,压缩机,烤漆房,吸尘器,制糖,洗衣机,贴片机,直饮机,水龙头,油烟机,空调 |

| 用途 | 防尘、除尘 |

| 类型 | 高效 |

| 适用对象 | 粉尘 |

| 编织方式 | 针刺 |

| 性能 | 防静电,防火,防水,防油,耐酸,耐低温,耐高温,耐碱 |

| 品牌 | AOBO |

| 型号 | AOBO-8 |

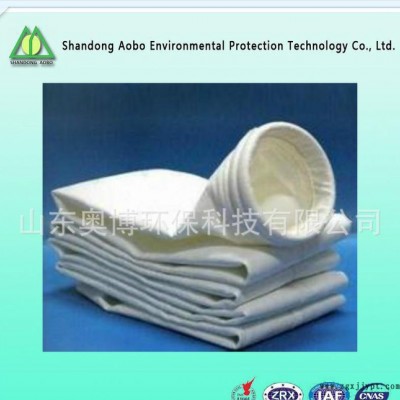

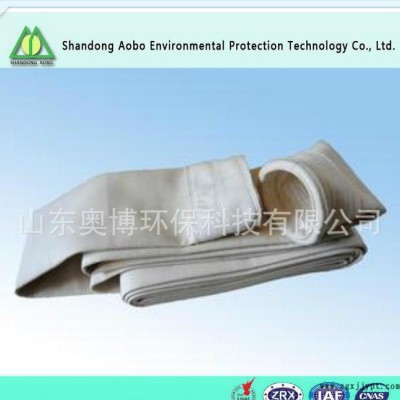

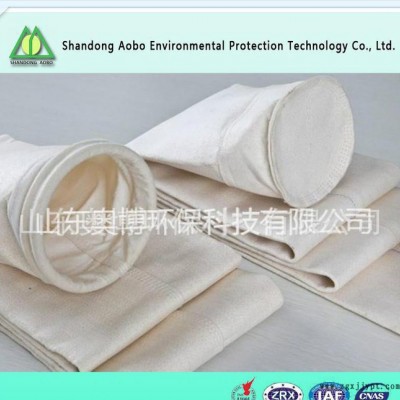

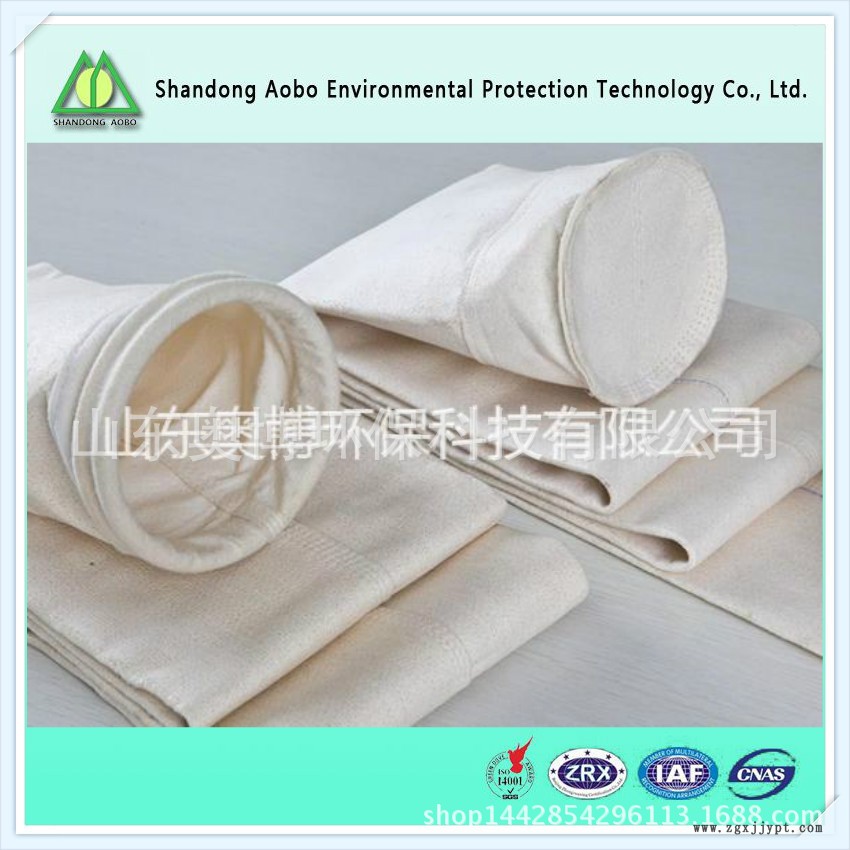

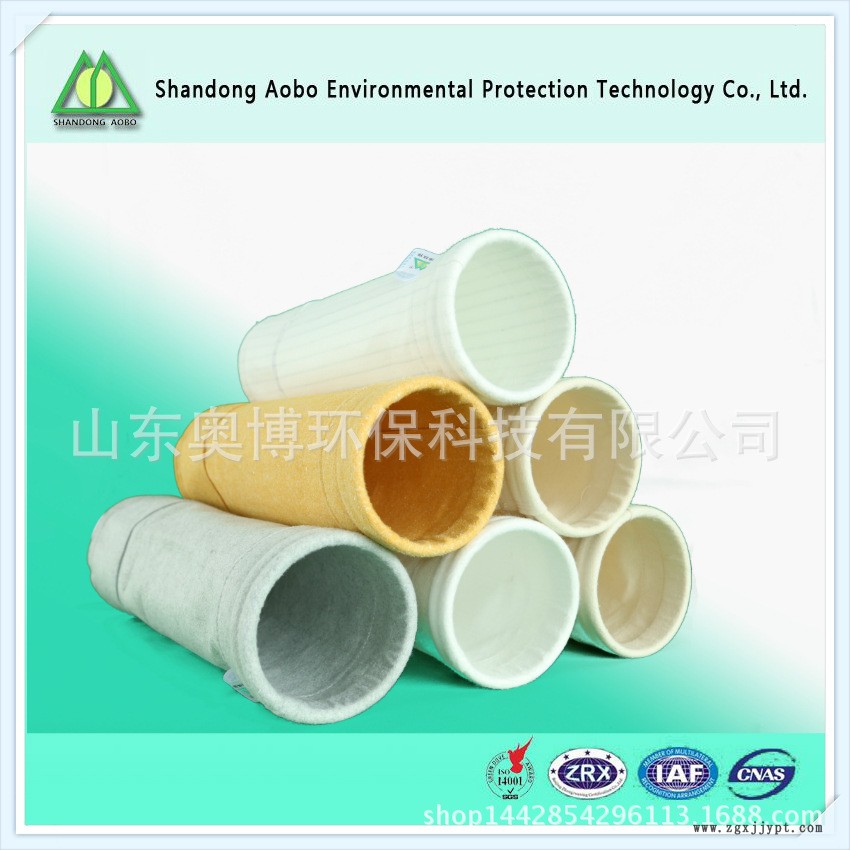

产品信息名称: PPS除尘滤袋品牌: AOBO 货号: AOBO-6 产品特点它具有强度的完整保持性和内在的耐化学性,可以在恶劣的环境中保持良好的过滤性能,并达到理想的使用寿命。具有耐热、耐化学性、阻燃性等诸多特性PPS运行温度为160℃-200℃。

1、 工作温度170℃,短时工作温度232℃,熔点285℃,极限氧指数34~35。2、 含氧量在15%或以下的场合均可适用。3、 燃料中含硫或烟道气中含硫的氧化物,现已证明其是抗酸碱腐蚀、抗化学性很强的纤维。4、 烟道中含湿气的场合。5、 在温度190℃~232℃工矿条件下,气布比高达5:1做线上清灰及气布比6:1做离线清灰时,PPS过滤毡除尘滤袋具有优异的性能记录。

PPS除尘滤袋介绍:

燃煤锅炉布袋除尘专用滤料(HAT系列PPS 滤料)是山东奥博环保科技有限公司在承担国家863课题干法脱除燃煤电厂多污染物协同控制技术的基础上,针对高温烟气除尘开发的纤维针刺毡滤料。具有除尘效率高,烟气阻力低的过滤特点。该滤料具有过滤精度高、排放低、性能稳定的特点。采用优质日本进口PPS纤维,经国内先进的成套针刺设备梳理织布,进行高温定型、表面轧光处理和高浓度PTFE浸渍防腐、防水防油处理后加工成针刺毡滤料。

滤袋纵向、袋口与袋底采用日本重机缝纫设备,用PTFE线进行缝制。滤袋袋口采用不锈钢弹性涨圈。袋底100mm双层加强。

产品特性:

优点:PPS纤维具有良好的耐腐蚀性、耐水解性。是目前燃煤锅炉除尘性价比较高的滤料。

缺点:不耐氧化。要求实际工况中含氧量要低于8%(150℃),温度越高含氧量应越低。温度每升高10℃,化学反应加倍。

执行标准:

1、环境保护产品技术要求—袋式除尘器滤袋 HJ/T327-2006

2、袋式除尘器技术要求 GB/T6719-2009

3、火电厂大气污染物排放标准 GB13223-2011

4、生活垃圾焚烧大气污染物排放标准DB11502-2008

应用场合:

1、燃煤锅炉布袋除尘器

2、半干法、干法脱硫布袋除尘器(电厂、钢厂烧结机)

3、生物质发电布袋除尘器

4、垃圾焚烧发电(流化床锅炉)

5、黄金冶炼收砷系统

6、冶炼厂冰铜干燥系统

7、高岭土除尘系统

性能参数:

序 号 | 名 称 | 单 位 | 参 数 | 备 注 |

1 | 纤维层 |

| 100%PPS | 梯度结构生产 |

2 | 基 布 |

| 100%PPS | 长丝基布 |

3 | 克 重 | g/m2 | 550 |

|

4 | 厚 度 | Mm | 1.8 |

|

5 | 透气量 | M3/m2.min | ≥15 |

|

6 | 纵向断裂强度 | N/5*20cm | ≥900 |

|

7 | 横向断裂强度 | N/5*20cm | ≥1000 |

|

8 | 长期使用温度 | ℃ | 露点温度以上,170℃以下 |

|

9 | 短时使用温度 | ℃ | 200 | 200每次不超过10min |

10 | 后处理 |

| 烧毛、轧光、高温定型、PTFE乳液浸渍防腐处理 表面防油防水处理 | |

公司一角

实验室

奥博是高端复合型人才孵化基地。现有工程技术人员40人,其中高级技术人员16人,中级技术人员8人, 每年委派不少于10人到高校进行培训,并聘请相关专家、教授进行指导,大力提升技术人员的研发能力。通过人才定向培养与交流,打造出一支精干、专业的科研队伍,为公司长期发注入了新的活力。

奥博立足科技创新,致力工业除尘,先后投资3000多万元,建成了2000多平方米的科研中心,成立了山东省袋式除尘唯一工程技术研究中心。公司先后引进数字式透气仪、电子织物强力机、全能型可见光谱分析仪、风动洞过滤效率测试线等研发试验设备30余台(套),总价值1000余万元,在国内同行业处于领先水平。

's high-end talents for incubators. Existing engineering and technical personnel 40 people, including senior technical personnel 16 people, intermediate technical personnel 8 people, appointed each year not less than 10 people to the training of colleges and universities, and invite relevant experts, professors, guide, vigorously promote technical personnel's research and development ability. Through the orientation training and communication, to create a compact, professional r&d team, long hair has injected new vitality to the company.

Ordered based on scientific and technological innovation, is committed to industrial dust removal, has invested more than 3000 ten thousand yuan, has built more than 2000 square meters of scientific research center, set up in shandong province, the only engineering technology research center of bag-type dust collector. Company has introduced digital air meter, electronic fabrics strength machine, universal visible spectrum analyzer, pneumatic hole filter efficiency testing line, such as research and development testing equipment more than 30 Taiwan (sets), the total value of more than 1000 ten thousand yuan, in the same industry in a leading level in China.

PPS除尘滤袋

孝义兴安化工有限公司热电厂 2*150MW机组袋式除尘配套工程 AOBO-2型PPS/PTFE滤袋 投运时间2012年、2014年 Xiaoyi sing-an chemical co., LTD. Supporting engineering of bag-type dust collector of 150 mw thermal power plant 2 * AOBO time - type 2 PPS/PTFE filter bag was put into operation in 2012, 2014

vsAOBO-除尘滤袋

兖矿集团国宏化工有限公司热电厂 3*50MW机组袋式除尘配套工程

AOBO-2型PPS/PTFE滤袋 投运时间2014年

Yankuang group, the macro chemical co., LTD. Power plant 3 * 50 mw unit supporting engineering of bag-type dust collector

AOBO time - type 2 PPS/PTFE filter bag was put into operation in 2014

企业介绍

截至目前公司共完成国家级科技创新项目四项(“863”、火炬计划、国家级新产品计划、创新基金),省级创新项目七项,市级技术创新项目十余项,已授权专利15项,其中发明专利4项。截止目前公司参与编制国家、行业和地方制标准六项,现在现行的山东省大气污染排放标注就是由我公司参与编制。标准的编制有力地提升了在行业制高点,有效地催生了市场,提升了产品的附加值。 公司现有生产和研发中心建筑面积达10万平方米,配备先进检测仪器设备30余台套。并与山东省科学院新材料研究所、东华大学和东北大学国家滤料检测中心建立了科技合作关系,成为合作单位硕士研究生工作站。公司技术中心2011年被山东省科技厅批建为“山东省袋式除尘工程技术研究中心”, 2012年被评为山东省企业技术中心。公司2013年被认定为省级高新技术企业。

依靠科技进步公司产品质量不断提高、商业模式不断更新市场份额逐年递增,在垃圾焚烧、钢铁冶金、燃煤电厂等相关除尘领域不断拓展,服务范围涉及滤袋销售、设备制造、服务外包运营、BOT项目等多种合作渠道,并成功与华能电力、华电国际、中联水泥等大型企业合作。

So far the company has completed four state-level scientific and technological innovation projects (" 863 ", the torch plan, national new product plan, innovation fund), seven provincial innovation projects, more than 10 municipal technical innovation projects, 15 authorized patents, of which 4 invention patents. So far the company to participate in the preparation of national, industry and local standard six, now the current atmospheric pollution emissions is marked by our company in shandong province to participate in. Standard establishment vigorously promoted the commanding heights in the industry, has given rise to market effectively, improve the added value of products. Company's existing production and research and development center building area of 100000 square meters, equipped with advanced testing equipment more than 30 sets. And new materials research institute of shandong academy of sciences (liao, donghua university and the university of the northeast countries test center set up scientific and technological cooperation relationship, become partners graduate workstation. Company technology center in 2011 is shandong province department of group building for engineering technology research center of bag-type dust collector in shandong province ", was named in 2012 in shandong province enterprise technology center. The company in 2013 was identified as the provincial high-tech enterprises.

Rely on scientific and technological progress the company constantly improve the product quality and business model updating market share is increasing year by year, in waste incineration, steel, metallurgy, coal power plant dust areas related to continue to expand, services ranging from filter bag sales, equipment manufacturing, service outsourcing operations, BOT project, and other channels of cooperation, and success and huaneng power, huadian power international, China united cement and other large enterprises.

企业证书