| 产品类型 | 全新 |

|---|---|

| 产地 | 广东 |

| 产品别名 | 平顶水平连续发泡 |

| 产品用途 | 生产海绵 |

| 类型 | 全新 |

| 用途 | 生产长泡海绵 |

| 适用行业 | 海绵厂 |

| 品牌 | 正兴诚信 |

| 型号 | ZX-S2009 |

| 加工定制 | 是 |

1 水平连续发泡机ZX-S2009

Horizontal continuous foaming machine ZX-S2009

概 述

本连续发泡机把溢流槽发泡和上浇式发泡巧妙地结合在一起,它突破了传统发泡由下向上的发泡方法,聚集国内外发泡机械优点于一体,并结合我国国情开发出来的新一代水平连续发泡机。

2.机器主要技术指标:(1)产量:40~280kg/分钟。(2)发泡密度范围:8~60密度。(3)泡绵宽度1米~2.2米(可调)。(4)主机总重:30吨。(5)机器工作环境温度:-20℃~+40℃。(6)工作形式,上浇式/溢流槽式两用。(7)主机外型尺寸:长27米×宽3米(未计后段输送带及油罐尺寸)。 (8) 机器总功率110KW; 电压:380V。

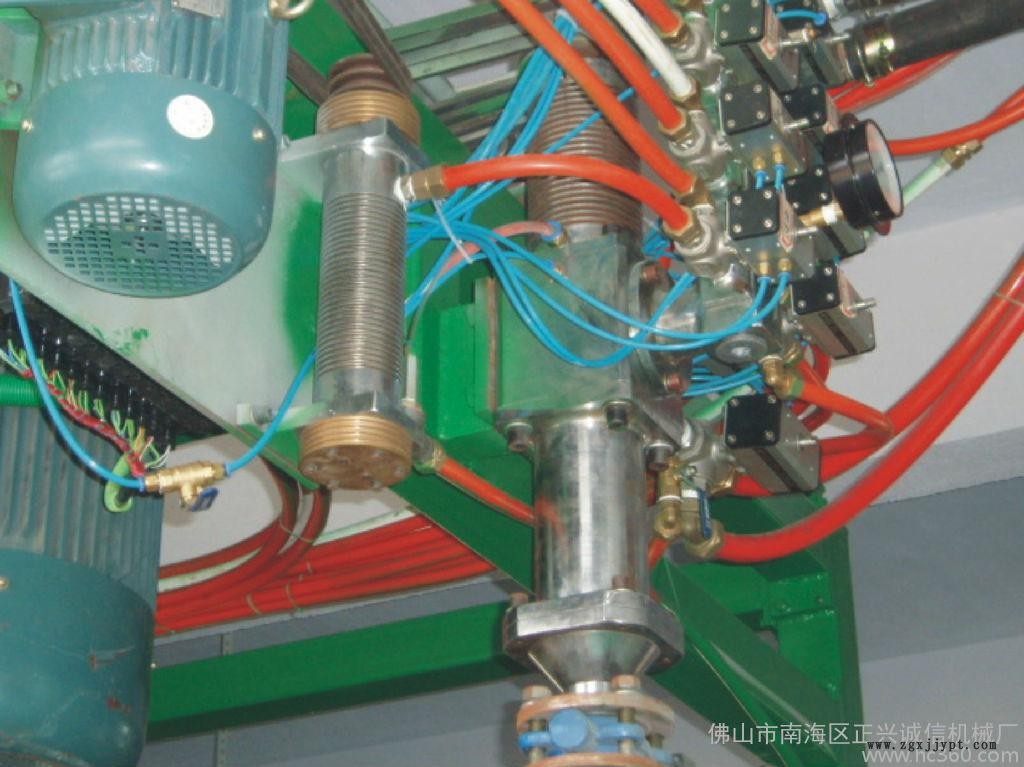

3.基本结构

本机由主料罐、计量系统、控制电路、混合器、布料机构、沉降板、熟化箱、放纸机构、收纸机构、切断机、后段输送带等十一部分组成。

4.工作原理

本机将海绵原料由贮料罐恒温后,由计量系统按比例输送到混合器高速搅拌,布料机构将原料均匀浇到纸模上,然后送到熟化箱聚合反应定型,经切断机按需要切成一定长度的块料**由输送带输送出成品海绵,即完成海绵生产流程。

安全注意事项 1、生产车间必须保持通风良好。 2、海绵及原料是易燃物,应切实做好防火工作,海绵生产出来后,有自燃的可能性,必须对其监测6小时以上。 3、海绵原料M.C、TDI为有毒物质,操作时必须严防溅入眼睛和口鼻等处,如果误入眼睛必须马上用大量清水冲洗,再到医院**诊。 4、机械必须接地良好。 5、非专业人员不得擅自打开电箱,否则有触电的危险,机械检修前应切断电源,带电检修必须做好安全防护工作,以免发生危险。 6、机器使用完毕应及时关闭电源,防止机器长时间通电而影响使用寿命。 7、切断机使用完毕后,自动开关必须打到手动位置,以防维护时引起误动作而发生危险。 8、M.C油罐在加料和发泡前必须打开顶部排气阀,以防加料时压力升高引起危险。 9、混合器严禁长时间空转(允许空转时间约15秒),长时间空转混合器,会导致轴承严重磨损。 10、各组份油泵,不得长时间高速空转,低速空转时间不得超过30秒。 11、主混合器、硅油混合器、油泵必须按规定方向运转。 12、主混合器不得缺油运行,否则容易损坏密封圈及轴承。 13、各工作人员操作时应戴好防护眼镜、防毒口罩和手套。

原料的降温

本机用冷水循环降温,当原料温度超过发泡工艺要求的温度时,开启冷水机降温。

本机顺序: a、打开需要降温的贮料罐进水阀。 b、打开冷水机冷却塔的补水阀。 c、打开冷水机冷水回流阀。 d、开启冷却塔和水泵电源。 e、开启压缩机电源,机器开始制冷,当压缩机超温报警不制冷时,关闭压缩机电源过几分钟重新开机即可。

原料的加热

当天气寒冷,原料温度低于工艺要求的温度时,用热水炉对原料进行加热,本机采用热水循环方式加热。

Horizontal continuous foaming machine ZX-S2009

introduction

This machine features with new foaming way of spraying from top and it combines with the advantages of tub foaming and the top spraying one.

Machine parameter: (1) output: 40-280kg/minute. (2) foaming density: 8-60 . (3)foam block width: 1-2.2 meter(adjustable).(4)machine weight:30 tons.(5)temperature for machine working: -20℃~+40℃.(6) work form: suitable for tub foaming and top spraying both.(7) machine outer size:L27xW3(exclusive of conveyor and tanks).(8) machine total power:110 KW. Voltage: 380V.

3. Structure:

This machine contains material tanks, measuring systems, controlling circuit, mixer, material spraying device, falling plates, oven, paper spreading/unreel device, foam cutter and conveyor.

Work process

After keeping constant temperature in the tank, the materials will be sent to mixer by measuring system and mix with high speed. Materials will be sprayed even to the paper and will react to finalize the block in the oven.

Caution:

1.Plant should be well ventilated;

2. Foam block and its materials are flammable and the products from this machine should be placed separated /monitored for 6 hours.

3. MC .TDI are poisonous and operator should be well aware of this.

4. Machine must be grounded.

5. Laypeople’s opening electricity box not allowed. Before fixing the machine, power supply must be cut off.

6. Power supply should be turned off after use to extend the life;

7. The cutter’s auto operation button must be turn to the position of

MANUAL to avoid accident;

8. When pouring the M.C and before forming, the exhaust valve on the top of tank must be open;

9. Mixer’s running without materials inside that exceed 15 seconds prohibited. Otherwise, bearing will get abraded.

10. Pumps of all materials will not be allowed to run at high speed without materials and the run at low speed without materials should not exceed 30 seconds.

11. Main mixer, silicon mixer and oil pump must run at the designated direction.

12. Main mixer must run with lubricant.

13. Operators must wear protective glass, mask and gloves.

Materials cooling:

This machine adopts water circulation cooling way and when the materials exceed the designated temperate that suitable for foaming, switch on the cooling unit.

Operation:

a. Open the water inlet valve of the material tank;

b. Open the water inlet of the cooling tower;

c. Open the cold water circumfluence valve;

d. Switch on the power of cooling tower and pump;

e. Switch on the power of compressor and machine starts cooling. If the compressor alarms and stops cooling, switch off the power and resume after minutes.

Material heating:

When the weather is cold and the material temperature is lower than the designated temperature that suitable for foaming, heat up the material with hot water stove. This machine adopts water circulation heating way.

www.zhx666.com 0757-86583300