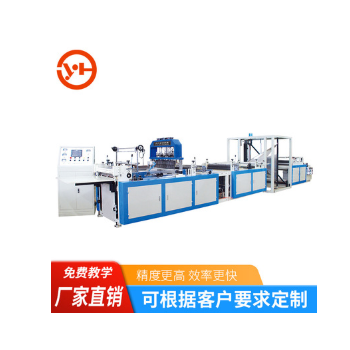

- 品牌/型号:南墩/CSB-600/800

- 类型:无纺布制袋机

- 重量:1500(kg)kg

- 外形尺寸:6×3×1.8(m)mm

技术参数Specification:

1 | 单片膜料宽度:1200mm Single sheet film width: 1200mm |

2 | 热成筒卷折径:600mm Roll folding diameter: 600mm |

3 | 卷料直径: 650mm Max. diameter of roll material: 650mm |

4 | 纠偏长度:左右各70mm Edge guider position length:±70mm |

5 | 工作速度:10-80 pcs/min Capacity: 10-80 pcs /min |

6 | 主电机功率:2.2kw Main motor power: 2.2kw |

7 | 超声波总功率 : 8.8kw Ultrasonic wave power:8.8kw |

8 | 工作电压 : 380v/50Hz or 220v/60Hz Working voltage : 380v/50Hz or 220v/60Hz |

9 | 外型尺寸: 8800mm x 1500mm x 1800mm (长 x 寛 x 高) Dimension: 8800mm x 1500mm x 1800mm ( L x W x H) |

主要功能及配置Main Function & Collocation:

电器配置部分Electric part | |

1 | 伺服马达(日本安川) Servo motor: Yaskawa, Japan |

2 | 伺服驱动器(日本安川) Servo driver: Yaskawa, Japan |

3 | PLC(三菱)触摸显示,微机电脑控制 PLC(Mitsubishi Japan)touch screen display(Eview Taiwan),Microprocessor Control |

4 | 变频调速控制:台湾爱得利 Speed regulation inverter: ATTLEE, TAIWAN |

5 | 光电眼跟踪(德国SICK) Photocell sensor: SICK ,German |

6 | 自动感应送料 Auto feeding |

7 | 气动元件(台湾亚德客) Solenoid pneumatic component: Airtac, Taiwan |

8 | 开关按钮(施耐德) Switch : Schneider |

9 | 5个超声波:2个台湾京华,3个中国 5Ultrasonic:2 fromK-SonicTaiwan,3from China |

机械工艺部分Machine function part | |

1 | 放料自动纠偏(E.P.C feeding) |

2 | 双折边装置 double folding device |

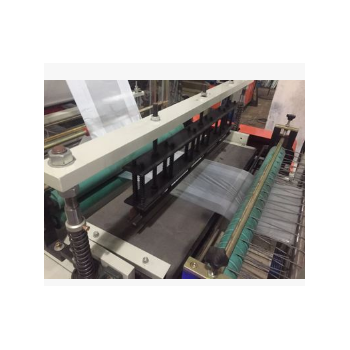

3 | 双滚花超声波压边(Ultrasonic side pressing) |

4 | 储料夹送(Storage feeding) |

5 | 对折装置三角架(Half-folding tripod) |

6 | 超声波压折线(ultrasonic line pressing) |

7 | 夹送储料(Storage seeding) |

8 | 超声波压边点花(Ultrasonic lace pressing) |

9 | 插立体底装置(Gusseting bottom devicev |

10 | 夹送储料(Storage feeding) |

11 | 同步供料(In phase feeding) |

12 | 张力浮动辊(Tension fluctuate roller) |

13 | 手挽孔冲模(Loop handle punching) |

14 | 光电眼追色(Photocell sensor ) |

15 | 封边超声波下座机构(Ultrasonic sealing) |

16 | 封切线调节(Sealing and cutting regulation) |

17 | 拉料送袋(Pulling and bag sending) |

18 | 冷切刀机构(Cold cutter institution) |

19 | 整本台(In lot unit) |

20 | 自动夹袋(Automatic bag feeding) |

21 | 冲口机台(Punching T-SHIRT unit) |

22 | 成品台传送(Finished product transmission) |